CUT EDGE CORROSION SPECIALISTS

As cut edge corrosion specialists, the Tritec team carry out cut edge corrosion treatment, an enevitable part of having Metal Roofing Sheets.

The machine cut edges to the sheets, which eventually peels back the paint away from the metal substrate, being exposed to the elements causing cut edge corrosion.

How you manage this is extremely important, left untreated will cause very costly remedies in the future.

The UK's Cut Edge Corrosion Specialists

Tritec can offer the best cut edge corrosion treatments as leading, heavily experienced, cut edge corrosion specialists in the UK.

Comprehensive guarantees are supplied as standard on all treatments installed by our team.

What is Cut Edge Corrosion?

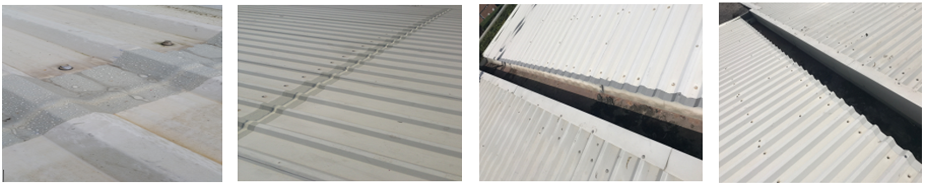

Cut edge corrosion develops 99% of the time on cladded roofs and in some instances on vertical cladding panels.

Over time the machine cut edges on the sheets are the most vulnerable to the natural elements.

The process begins with the Plastisol or PVC coating peeling back from the metal substrate, exposing it to air and water causing erosion.

Roof Treatments by Cut Edge Corrosion Specialists

The areas where cut edge corrosion can be commonly found is on leading gutter edges, intermediate lap joint and ridge and hip joints.

Overlapped joints remain especially vulnerable due to the effects of capillary reaction drawing sulphur contaminated rainwater into the joint causing the double hazard of 'topside' and 'reverse' side corrosion.

BENEFITS OF CUT EDGE CORROSION ROOF TREATMENTS

Saves hefty long-term costs

Not only can cut edge corrosion save you money in the long run, but having Tritec manage the job can save you even more money in the long-term.

We ensure that your cut edge corrosion problems are treated efficiently and at an affordable price.

Cold applied

Our cut edge corrosion roof treatments are cold-applied, meaning they are much cheaper than the alternatives.

It also means that they’re much safer because there is no risk of fire on application and the nature of the materials makes them suitable for many different situations.

Variety of systems to suit all budgets

No matter your budget, we can ensure that we have a cut edge corrosion roof treatment that suits your budget and needs.

We understand that having your roof treated can be expensive, which is why we strive to bring you a variety of different service levels to ensure that you can utilize our services no matter how much you’re able to invest and get the best bang for your buck.

UV and corrosion resistant

Having your cut edge corrosion treatment be resistant to the sun and further corrosion is important to ensure the quality of the treatment itself.

The treatment won’t last long if it suffers damage from UV rays or other effects, which is why we ensure that our jobs are long-lasting and can withstand a variety of different effects.

All treatments guaranteed

All of the cut edge corrosion treatments we perform are guaranteed.

This will give you peace of mind knowing that your roof is in safe hands and that it will last a long time.

Our reputation is important and we would never risk it on a shoddy job.

All of our fitters are well-trained and experienced, helping to guarantee the effectiveness of our cut edge corrosion treatments.

Easy installation

We ensure that all you need to do is sit back and relax when we’re performing our cut edge corrosion treatments.

Your job is safe in our hands and there’s nothing you need to do outside of calling us and arranging for an inspection.

Can be used in conjunction with full roof re-coats

Our treatments are fully compatible with full roof re-coats as well, making them a convenient and efficient way to improve the overall quality of your roof.

Nationwide service

Our services are available across the entire nation. We’re able and willing to visit you regardless of where you are.

We’ll perform our initial inspections and follow up with further work as required.

GET A CUT EDGE CORROSION TREATMENT QUOTE

REQUEST A FREE QUOTE

What is Cut Edge Corrosion?

Cut edge corrosion develops 99% of the time on cladded roofs and in some instances on vertical cladding panels. Over time the machine cut edges on the sheets are the most vulnerable to the natural elements. The process begins with the Plastisol or PVC coating peeling back from the metal substrate, exposing it to air and water causing erosion.

Roof Treatments by Cut Edge Corrosion Specialists

The areas where cut edge corrosion can be commonly found is on leading gutter edges, intermediate lap joint and ridge and hip joints. Overlapped joints remain especially vulnerable due to the effects of capillary reaction drawing sulphur contaminated rainwater into the joint causing the double hazard of 'topside' and 'reverse' side corrosion.

WHAT IS CUT EDGE CORROSION TREATMENT?

A member of our team will survey and assess the extent of the condition of the cut edge and conclude the best solution and treatment.

Preparation is carried out to manufacturers specification. Generally abrading corroded surface back to a Swedish Std 3 removing corrosion, flakes, loose materials etc leaving clean and dry.

A base coat / primer will be applied to prepared surfaces allowing 24 hours to cure.

With some systems overlapping joints are sealed with a sealant unincorporated with the base coat / primer.

Finished with a colour matching topcoat encapsulating all base coat / primer.

benefits of cut edge corrosion roof treatments

Saves hefty long-term costs

Cold applied

Variety of systems to suit all budgets

UV and corrosion resistant

All treatments guaranteed

Easy installation

Can be used in conjunction with full roof re-coats

Nationwide service

testimonial

Principal Contractor review on Tritec

"I have worked with Tritec for over 3 years now, with them being our primary Giromax and roof coatings contractor. They are without a doubt the best and most efficient contractor I have used. Their work is always to the highest standard of workmanship and their management team always produce a fast and reliable tender return. I are happy to recommend them to any one of our contractors or anyone who wishes to enquire about their services."

Terry Prokopcruik - 25th October