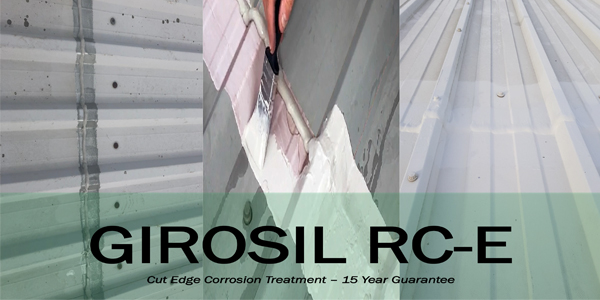

Cut Edge Corrosion Treatment – Advanced Profiled Steel Sheet Repair

GIROSIL® EDGE RC-E is the revolutionary next generation of coatings from Giromax, designed to treat both the top and reverse side of the cut edge through advanced corrosion treatment and encapsulation

Uniquely, both GIROSIL® Base and GIROSIL® SE Sealant stabilise the substrate using laminar flake technology that seals and bonds with corrosion. Solvent free GIROSIL® Edge RC-E then prevents rainwater re-entering the lap. It can easily accommodate sheet movement and remains unaffected by UV and temperature. Fully moisture tolerant, it can be applied in the wet and hardens to a tough elastic coating with high impact and dirt resistance.

Key Benefits:

Fully Moisture Tolerant system using laminar flake technology for matchless corrosion control.

Proven long life, being unaffected by UV or extremes of weather and temperature.

Excellent elastic and flexibility properties to withstand normal surface movements.

Instructions for Use:

GIROSIL® EDGE RC-E has been developed against a background of decades of experience of roof refurbishment and repair and is designed as a two stage application. Fully moisture tolerant, GIROSIL® Base quickly cures to allow a follow on installation of GIROSIL® SE sealant and GIROSIL® EDGE RC-E Topcoat that requires little in the way of expensive application equipment.

Specifications where Girosil RC-E would be used:

Specification Used: Cut edge corrosion treatment on profiled steel roofing

Specification Used: Gutter joint sealing

Specification Used: Hook bolt and local encapsulation on asbestos cement sheeting

- Specification Used: Profiled metal sheet and rooflight lap seal

GIROSIL® Edge RC-E Approved Applicators:

Tritec Building Contractors Ltd have been fully trained and approved by Giromax with the task of installing Girosil® RC-E. Loose and flaking coatings, surface corrosion, swarf and debris are completely removed and abraded back to a firm adhered edge, this ensures the substrates are structurally sound and suitable for treatment. We then clean the surface and apply the Girosil® Basecoat allowing sufficient time to cure and fully seal with Girosil® SE & Girosil® RC-E Topcoat.

Girosil Edge RC-E is used in conjunction with the following products:

GIROSIL® BaseCoat: One-part anti-corrosion coating, brush or roller applied onto ST2 prepared steel substrate. Tolerant of damp and humid conditions.

| Curing System: | Moisture | Specific Gravity: | 1.1 |

|---|---|---|---|

| Min. WFT / DFT: | 100 μm / 55 μm | Volume Solids | 55% |

| Max. WFT / DFT: | 145 μm / 80 μm | Theoretical (50mm band): | 200 lm / Lt |

| Application Temp: | 0ºc /+35ºc | Overcoat Time: | 2-3 hrs |

| Supplied in: | 1 & 2.5 Lt | VOC: | 381 g / Lt |

GIROSIL® SE: Gun-grade one-part modified polymer sealant incorporating laminar flake technology. Tooled with RoofCoat RC for lap sealing.

| Curing System: | Moisture | Colour: | Grey |

|---|---|---|---|

| Shore A (Typical): | 55 | M/ment Accom. | ± 70% |

| Tensile at break: | 1.85 N/mm² | Elong. at Break: | 220% |

| Application Temp: | 0ºc /+35ºc | Skin Time@ 20oC | 15 mins |

| Service Temp: | -40ºc/+120ºc | Cure @ 20oC | 2mm/24hr |

| Supplied in: | 310ml tube | UV Resistance: | Excellent |

GIROSIL® RC: Brush-grade, one-part solvent free silicone hybrid coating. Moisture tolerant, flexible and UV, temperature and impact resistant.

| Curing System: | Moisture | Colour: | Various |

|---|---|---|---|

| Shore A (Typical): | 55 | Volume Solids | 100% |

| WFT / DFT: | 200 μm | Theoretical (75mm band): | 66 lm / Lt |

| Application Temp: | 0°c /+60°C | Skin Time @ 20°C | 2-4 hours |

| Service Temp: | -40ºc/+120ºc | Cure Time @ 20°C | 16 hours |

| Supplied in: | 2.5 & 5 Lt | VOC: | 0 g / Lt |

testimonial

Review on Girocote

"Malcolm Hollis contacted Tritec Building Contractors Ltd for application of Giromax Girocote to front facade cladding, windows, doors and shutters. The job was completed in very good time and of a high standard."

Shane Lowry - Malcolm Hollis